Khadka Tooska ah ee Mashiinka Daloolinta ee Marble

HORDHAC

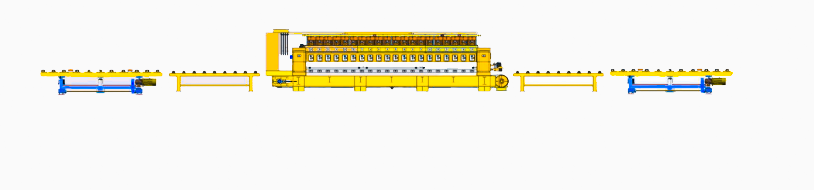

Mashiinkan si toos ah u dhalaalinaya waxa loogu talagalay in lagu shiido oo lagu sifeeyo oogada marble.

Iyadoo 10/12/16/20/24 madax dhalaalaysa la heli karo.

Mashiinka dhalaalka marmarka ah wuxuu qaataa horumarinta naqshadeynta Talyaaniga iyo nidaamka xakamaynta tooska ah.Waa nooc cusub oo is dhexgalka oo hufnaan sare leh, qiimo jaban, hawlgal fudud oo waara.

Dabaqyada aan la farsamayn waxay galaa suunka gudbinta fidsan ee gawaarida rollerka ah, suunka gudbinta fidsan ka dib wuxuu keenaa dhejisyo hoos yimaada madaxyo dhalaalaysa oo wareeg ah. gadaal, jihada wareega waa ka soo horjeeda labada madax kasta polishing, Sida laga soo xigtay shuruudaha kala duwan ee shahaado la safeeyey, hagaajin karaa xawaaraha suunka gudbinta suunka iyo xawaaraha lulida buundada by transducers, si ay u gaaraan waxqabadka ugu wanaagsan ee loo baahan yahay.

Marble Polisher waxay qabataa nidaamka xakamaynta terminalka PLC, hawl wadeenadu waxay si xor ah u dejin karaan cabbirka kantaroolaha barnaamijka ee leh shaashadda LCD.

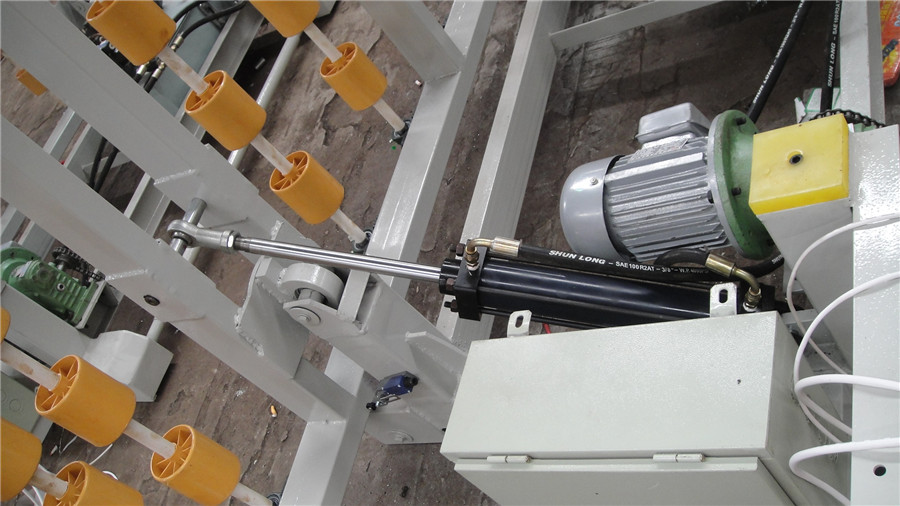

Nidaamka wadista wuxuu ku yaalaa booska qaybta sare, kaas oo si fiican u ilaalin doona si looga takhaluso boodhka.

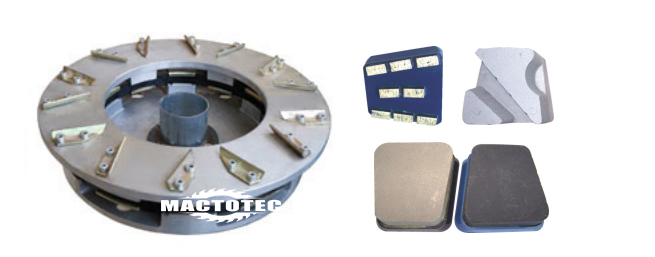

Waxay ku qalabaynaysaa nidaamka tilmaamaya cilladda iyo nidaamka digniinta isticmaalka nabarrada.si loo hubiyo oo loo xukumo xaalada xidhashada naaxinta iyadoo la hagaajinayo booska beddelka magnetka ee dhululubada ee sare ee madaxa.Marka nabarku hoos u dhaco booska xaddidan, waxay soo diri doontaa digniinaha digniinta la'aanta.

Suunka wax qaada iyo laydhka iskutallaabta waxay qaataan beddelka soo noqnoqda ee hagaajinta xawaaraha.Balaadhkeeda farsamaynta iyo cadaadiska shaqada ee madaxyada shiidi kara si xor ah ayaa loo hagaajin karaa,

Mashiinka qurxinta dhagaxa ayaa si otomaatig ah u aqoonsan kara qaabka xargaha, Waxaa jira nidaam aqoonsi otomaatig ah oo loogu talagalay qaababka dhejiska ee qaybaha soo galaya, nidaamka xakamaynta tooska ah ayaa wax ka qaban doona calaamadaha laga helay dareemayaasha wuxuuna xukumi doonaa qaababka habka loo shaqeeyo, si loo hubiyo sax oo wax ku ool ah kor iyo hoosba ee madaxyada turxaan bixinta

Mashiinka polishing ee marmarka ah waa mishiin culus oo isticmaala birta iyo birta wax shubaya oo tayo sare leh, qalab elektaroonik ah oo magac leh, biraha iyo qaybaha kale.

PLC: MITSUBISHI

Beddelka: SCHNEIDER

Xiriiriyaha: Fuji

(Madaxa Frankfurt ee ballaca Marble 1250mm)

Xogta farsamada

| Qaabka |

| MTWY-M12-1250 | MTWY-M16-1250 | MTWY-M20-1250 | MTWY-M24-1250 |

| Qty.Madax dhalaalaysa | kumbiyuutarada | 12 | 16 | 20 | 24 |

| Max.Balaadhka salax | mm | 1250 | 1250 | 1250 | 1250 |

| Xawaaraha Swing Beam | m/min | 3-35 | 3-35 | 3-35 | 3-35 |

| Awooda Baabuurka Wadista ee Beam | kw | 6 | 6 | 6 | 6 |

| Xawaaraha wareejinta suunka | m/min | 0.5 ilaa 4.0 | 0.5 ilaa 4.0 | 0.5 ilaa 4.0 | 0.5 ilaa 4.0 |

| Awood wareejinta suunka | kw | 3 | 3 | 3 | 3 |

| Cadaadiska Biyaha Qaboojinta | mpa | 0.1-0.15 | 0.1-0.15 | 0.1-0.15 | 0.1-0.15 |

| Xoogga Cadaadiska ee Compressor | mpa | 0.7 | 0.7 | 0.7 | 0.7 |

| Awoodda Matoorka ugu weyn | kw | 9 ~ 11*12 pcs | 9 ~ 11*16 pcs | 9 ~ 11 * 20 pcs | 9 ~ 11*24 pcs |

| Isticmaalka Biyaha | m³/h | 15 | 20 | 24 | 30 |

(Madaxa Frankfurt ee ballaca Marble 2000mm)

Xogta farsamada

| Qaabka |

| MTWY-M10-2000 | MTWY-M12-2000 | MTWY-M16-2000 | MTWY-M20-2000 |

| Qty.ee Madaxyada Polishing | kumbiyuutarada | 10 | 12 | 16 | 20 |

| Max.Balaadhka caleenta | mm | 2000 | 2000 | 2000 | 2000 |

| Xawaaraha Swing Beam | m/min | 3-35 | 3-35 | 3-35 | 3-35 |

| Awooda Baabuurka Wadista ee Beam | kw | 6 | 6 | 6 | 6 |

| Xawaaraha wareejinta suunka | m/min | 0.5 ilaa 4.0 | 0.5 ilaa 4.0 | 0.5 ilaa 4.0 | 0.5 ilaa 4.0 |

| Awood wareejinta suunka | kw | 3 | 3 | 3 | 3 |

| Cadaadiska Biyaha Qaboojinta | mpa | 0.1-0.15 | 0.1-0.15 | 0.1-0.15 | 0.1-0.15 |

| Xoogga Cadaadiska ee Compressor | mpa | 0.7 | 0.7 | 0.7 | 0.7 |

| Awoodda Matoorka ugu weyn | kw | 15*10 pcs | 15*12 pcs | 15*16 pcs | 15*20 pcs |

| Isticmaalka Biyaha | m³/h | 8 | 10 | 15 | 20 |